At Crosslink we often get asked what is the difference between pot life and working time? Or, what does green strength mean exactly?

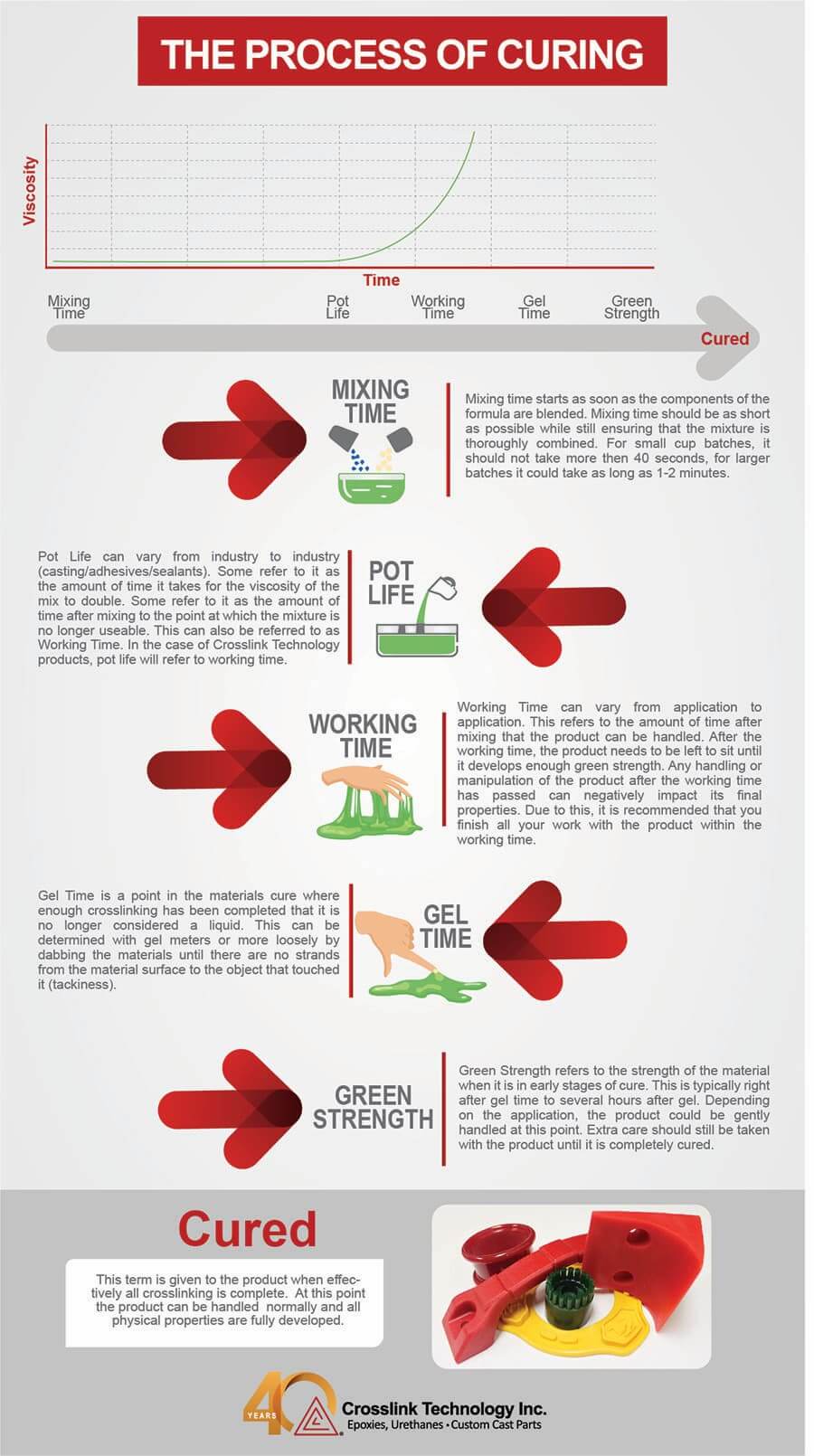

To help better understand the sequence and timeline of curing, we have created the below infographic and definitions for each curing milestone.

Mixing Time starts as soon as the components of the formula are blended. Mixing time should be as short as possible while still ensuring that the mixture is thoroughly combined. For small cup batches, it should not take more then 40 seconds, for larger batches it could take as long as 1-2 minutes.

Pot Life can vary from industry to industry (casting/adhesives/sealants). Some refer to it as the amount of time it takes for the viscosity of the mix to double. Some refer to it as the amount of time after mixing to the point at which the mixture is no longer useable. This can also be referred to as Working Time. In the case of Crosslink Technology products, pot life will refer to working time.

Working Time can vary from application to application. This refers to the amount of time after mixing that the product can be handled. After the working time, the product needs to be left to sit until it develops enough green strength. Any handling or manipulation of the product after the working time has passed can negatively impact its final properties. Due to this, it is recommended that you finish all your work with the product within the working time.

Gel Time is a point in the materials cure where enough crosslinking has been completed that it is no longer considered a liquid. This can be determined with gel meters or more loosely by dabbing the materials until there are no strands from the material surface to the object that touched it (tackiness).

Green Strength refers to the strength of the material when it is in early stages of cure. This is typically right after gel time to several hours after gel. Depending on the application, the product could be gently handled at this point. Extra care should still be taken with the product until it is completely cured.

View some of our easy to use Cartridge Systems, or feel free to learn more about our processing Tips and Tricks.