Variety of casted urethane parts

" Lower your costs and your footprint by switching to cold casting "

Handling Guide | Physical Properties

Triathane® is a 3-component variable mix-ratio polyurethane system. This unique formula was developed to provide processors with a convenient and less labour-intensive method for achieving a wide range of cured hardness properties. With Triathane® you can achieve 18 unique hardness systems, whereas, conventional thermosets would require 36 different components.

The Benefits of Cold Casting with Triathane

![]() Superior versatility. Triathane® can achieve 18 different hardnesses with only 3 components

Superior versatility. Triathane® can achieve 18 different hardnesses with only 3 components

![]() Room temperature operation, meaning no messy melting or warming of raw materials

Room temperature operation, meaning no messy melting or warming of raw materials

![]() A 20-30% savings in energy costs

A 20-30% savings in energy costs

![]() Changing cured hardness without formulating or compounding products

Changing cured hardness without formulating or compounding products

![]() Improved logistics and storage space, with no need to stock different products

Improved logistics and storage space, with no need to stock different products

![]() Always in stock and quickly shipped, minimizing downtime for your business

Always in stock and quickly shipped, minimizing downtime for your business

Industrial Belts

Crosslink’s pre-determined mix ratio combinations allow you to eliminate the necessity of stocking and loading different products into your processing equipment every time a change in cured hardness is required. By only stocking 3-components you’re also achieving significant savings for the environment, budget and in product.

All the urethane components are low in viscosity and do not require heating to obtain suitable processing conditions. Unlike hot-cast type urethanes, there is no need to formulate and/or compound different products to change the cured hardness.

Schedule a consultation with one of our experts to learn more!

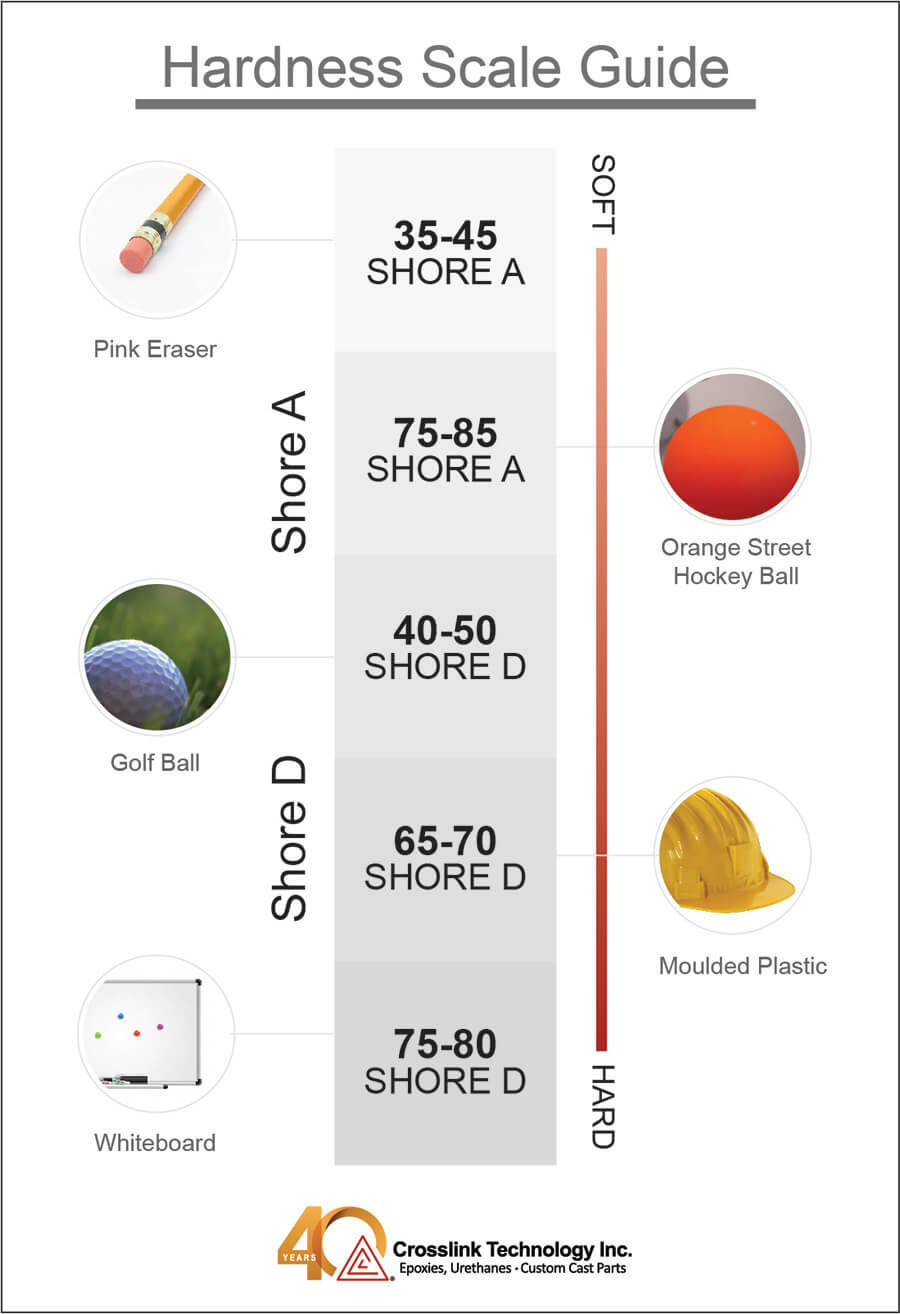

With only Triathane® achieve hardness 10 to 90 Shore A

Shore Hardness Scale Examples