Transformer bushings are components of critical importance in the operation of a transformer. Their failure is one of the major causes of transformer failures, which sometimes can lead to fatal consequences, such as explosions, fires and oil spills.

A failed transformer bushing can thus cause a lot of trouble in the field. Not only is there a significant cost to replacing the bushing, but also the resulting transformer failure can incur additional costs, much higher than the cost of the failed bushing, and lead to downtime resulting in more costs to the operator.

Additionally, there is the question of the reputation of the transformer supplier, as well as a possibility to be subjected to penalties for power interruptions and failure to deliver electricity to customers.

DOWNLOAD PDF SEE FULL MAGAZINE

Let’s look at the most common causes of bushing failures, specifically in regard to polymer transformer bushings.

Part Design

Part design is regulated by standards such as those set by NEMA and IEEE. In addition to meeting these standards, part design is also closely related to and dependent on the properties of the polymer that is used to manufacture bushings. Fulfilling requirements such as creep distances, mounting, shed design and configuring cable connections is influenced, to some degree, by optimized polymer properties.

Things to look for in this area include the following:

![]() Optimizing thermal cycling ability – A good polymer must be able to withstand extreme temperature changes. If overloading/overheating occurs due to a poor contact, the bushing material may degrade. Therefore, it is important to know the glass transition temperature of the polymer. According to IEEE C57.19, the glass transition temperature must be higher than the allowed hot-spot temperature.

Optimizing thermal cycling ability – A good polymer must be able to withstand extreme temperature changes. If overloading/overheating occurs due to a poor contact, the bushing material may degrade. Therefore, it is important to know the glass transition temperature of the polymer. According to IEEE C57.19, the glass transition temperature must be higher than the allowed hot-spot temperature.

![]() Cantilever strength requirements – To ensure higher cantilever strength of the material, it is important that all welded joints are free of pores. A porous weld will cause hot-spots and lower the cantilever strength.

Cantilever strength requirements – To ensure higher cantilever strength of the material, it is important that all welded joints are free of pores. A porous weld will cause hot-spots and lower the cantilever strength.

![]() Maximizing creep and strike distances – Maximizing the creepage and strike distances of the insulator is essential in avoiding flash overs. To achieve this, all sharp edges should be rounded with radius. It is also important to have a good polymer in order to avoid dirt which, over time, may lead to flash over.

Maximizing creep and strike distances – Maximizing the creepage and strike distances of the insulator is essential in avoiding flash overs. To achieve this, all sharp edges should be rounded with radius. It is also important to have a good polymer in order to avoid dirt which, over time, may lead to flash over.

![]() Maximizing heat dissipation – In order to maximize heat dissipation it is important to ensure that the adhesion between the polymer and the conductor is not compromised. The adhesion between the polymer and the conductor will prevent any leakages during operation.

Maximizing heat dissipation – In order to maximize heat dissipation it is important to ensure that the adhesion between the polymer and the conductor is not compromised. The adhesion between the polymer and the conductor will prevent any leakages during operation.

Polymer

In bushing manufacturing, choosing the correct polymer, which is typically an epoxy system (resin/hardener combination) is critical. The epoxy must be carefully selected so that the combination of cured properties will accommodate the changing conditions encountered in service. This applies to both mechanical strength and electrical insulation properties. In general, careful consideration must be given to the following specific properties:

![]() Dielectric strength

Dielectric strength![]() Heat deflection temperature

Heat deflection temperature![]() Heat aging

Heat aging![]() Moisture absorption

Moisture absorption![]() Tensile strength

Tensile strength![]() % elongation

% elongation![]() Material type (for indoor or outdoor service)

Material type (for indoor or outdoor service)

These properties can be verified by standard test procedures.

Most Common Failures

The most common failures in the material include:

![]() Cracking

Cracking![]() Leaking bushings

Leaking bushings![]() Direct short to transformer tank (catastrophic failure)

Direct short to transformer tank (catastrophic failure)![]() Loss of dielectric properties over time (aging)

Loss of dielectric properties over time (aging)![]() Reduction in tracking resistance over time

Reduction in tracking resistance over time

Manufacturing

In bushing manufacturing different production methods are used. While some of these methods work quite well, others do not. The difficulty is that the customers buying the bushings have no way of confirming the quality of the product unless they do full testing on every bushing, which is not feasible.

In order to overcome this issue, it is essential to ensure whichever method is employed to manufacture the parts, it must be accurate and repeatable. For example, being off ratio in the resin/hardener mix is not readily detectable by the end user, but chances are that the bushing will fail in operation.

So, there is no room for error in the manufacturing process.

Some of the most common causes of failure that occur as a result of improper processing are:

![]() Insufficient conductor preparation – To avoid this, electrical grade copper must be used with proper brazing between the joints to ensure good contact. Poor contact will be the source of hot spots.

Insufficient conductor preparation – To avoid this, electrical grade copper must be used with proper brazing between the joints to ensure good contact. Poor contact will be the source of hot spots.

![]() Insufficient air removal from the mix – As a result of this, air voids may be trapped causing partial discharge (PD) and flash over.

Insufficient air removal from the mix – As a result of this, air voids may be trapped causing partial discharge (PD) and flash over.

![]() Improperly dispersed fillers within the epoxy mix – This weakens the integrity of the epoxy.

Improperly dispersed fillers within the epoxy mix – This weakens the integrity of the epoxy.

![]() Incorrect processing temperatures (epoxy, mould and conductor) – Applying incorrect temperatures may lead to void formation and cause the epoxy to be brittle, have poor adhesion, and shorter service life.

Incorrect processing temperatures (epoxy, mould and conductor) – Applying incorrect temperatures may lead to void formation and cause the epoxy to be brittle, have poor adhesion, and shorter service life.

![]() Off ratio epoxy mix – This compromises the integrity of the epoxy. It will not have full physical nor electrical properties to meet the requirements for its application.

Off ratio epoxy mix – This compromises the integrity of the epoxy. It will not have full physical nor electrical properties to meet the requirements for its application.

![]() Less than completely cured epoxy – This compromises the integrity of the epoxy.

Less than completely cured epoxy – This compromises the integrity of the epoxy.

![]() Inadvertent thermal cycling of components which are not fully cured – This may cause premature failure in the field and compromises the full potential of the epoxy.

Inadvertent thermal cycling of components which are not fully cured – This may cause premature failure in the field and compromises the full potential of the epoxy.

Most Common Failures

The most common failures that develop as a result of improper processing include:

![]() Bushing leaks developing over time in operation – Most commonly, bushing leaks are caused by ageing or by improper gaskets, as well as the weak adhesion between the epoxy and the conductor.

Bushing leaks developing over time in operation – Most commonly, bushing leaks are caused by ageing or by improper gaskets, as well as the weak adhesion between the epoxy and the conductor.

![]() Excessive partial discharge – If the material is not de-aired properly, this may result in excessive partial discharge.

Excessive partial discharge – If the material is not de-aired properly, this may result in excessive partial discharge.

![]() Cracking during mounting or under maximum cable load – Cracking can be caused by using improper epoxy. To avoid this problem, the epoxy should be customized to different temperatures.

Cracking during mounting or under maximum cable load – Cracking can be caused by using improper epoxy. To avoid this problem, the epoxy should be customized to different temperatures.

![]() Tearing when conductor temperature rises due to high current – In order to avoid this issue, it is important to know the coefficient of thermal expansion of the conductor and the epoxy as well as the Glass Transition Temperature

Tearing when conductor temperature rises due to high current – In order to avoid this issue, it is important to know the coefficient of thermal expansion of the conductor and the epoxy as well as the Glass Transition Temperature

Selecting Your Supplier

Considering the gravity of the consequences of a bushing failure, it is important to carefully select the supplier that is consistent and dependable.

An ISO quality system is a great place to start because consistency is an absolute must. This is important because for the end user it is not possible to detect all things in a bushing that can cause problems down the road, usually without warning.

It also helps to work with suppliers that are not only experienced in manufacturing the bushings, but also are capable of developing, formulating and manufacturing the epoxy resins used to make the bushings.

Some of the issues discussed above can be eliminated through "type testing” different parts because those properties will remain consistent as long as the supplier’s process is repeatable. On the other hand, issues related to the manufacturing process are of particular importance because they are truly dependent on consistency, while, at the same time, are difficult to detect by the user and will likely lead to field failures over time.

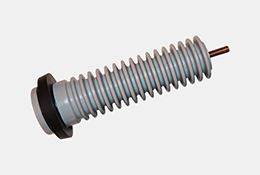

At Crosslink Technology, we are vertically integrated, developing, formulating and manufacturing our own epoxy resins, but also designing and manufacturing the bushings. Our Epoxy Transformer Bushings are manufactured to the highest quality standards and are available for both indoor and outdoor, and low to medium voltage use. Crosslink has 40 years of experience with no field failures.

Our epoxy bushings are non-tracking, and weathering resistant, so they offer outstanding performance in all types of environments, even highly contaminated areas. Far lighter (60% lighter) and sturdier (10 times the tensile strength) than porcelain, epoxy bushings will not crack due to thermal shock.

Epoxy bushings also have:

![]() A low partial discharge

A low partial discharge

![]() Superior Compression strength

Superior Compression strength

![]() Flexural strength of cycloaliphatic that is up to 15 times greater than porcelain

Flexural strength of cycloaliphatic that is up to 15 times greater than porcelain

![]() Resistance to high-power arcs (great dry arcing distance)

Resistance to high-power arcs (great dry arcing distance)